Disc Mill Machine

Details

Material MFI (g/10 min) Density (kg/m3) Fineness Output Cap.

LLDPE 4.5 938 18-150 # 10-200 kg/hr

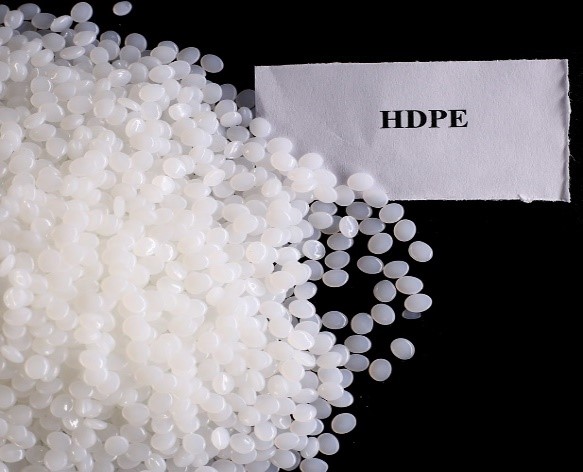

HDPE 0.90 952 10-60 # 10-200 kg/hr

LDPE 8.5 917 18-150 # 10-200 kg/hr

PP 2.16 230 10-30 # 10-200 kg/hr

EVA 2.3 216 18-80 # 10-200 kg/hr

PCB - - 18-50 # 10-200 kg/hr

Masterbatch 1.5 216 10-100# 10-200 kg/hr

ABS 18 104 18-40 # 10-200 kg/hr

Free flowing products resulting in lower fuels consumption.

● Uniform & smooth powder/particle size

● Microprocessor based machine control panel with digital display.

● Temperature indicator for monitoring and control

● Well designed cyclonic system for ease of cleaning with bag filter (on request)

arrangement.

● High efficient hopper magnet provided in hopper to detect the metallic parts from the

polymer. Optionally a metal detector sensor will be provided on request.

● Feeding hopper showing low-level indicator.

● Auto tripping system available in case of overload feeding. Main motor ampere and

feeding device are synchronized to avoid tripping the motor due to over feed.

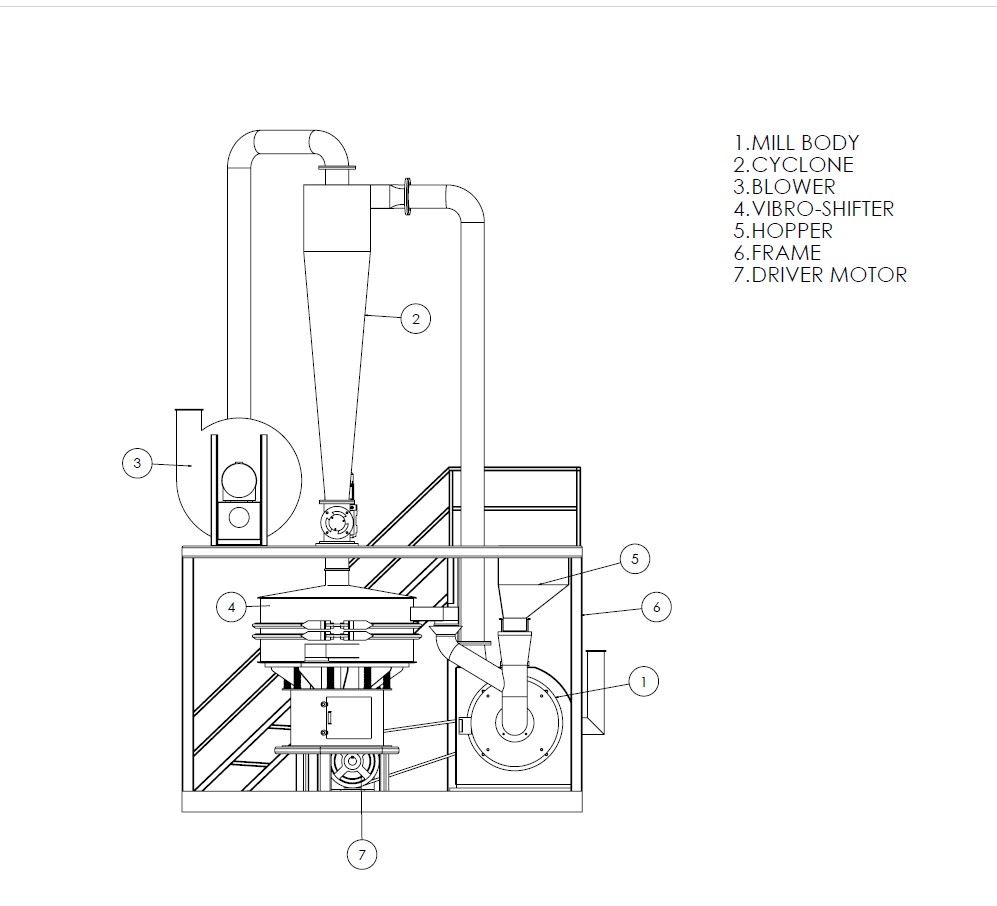

Disc mill is the type of attrition mill in which two surfaces rotate past each

other at high speeds with close tolerances.

● The Material is fed through a hopper into the center of the stationary grinding

disc straight into the grinding chamber.

● Rotating disc crushes the material by attrition force at great speed until it is

fine enough to exit from the gap at the edges of the disc.

● The crushed and ground material is then fed into a collecting vessel.

VIDEO

Industries

- Plastic Industry

- Foods Industry

- Herbs Industry

- Chemical Industry

- Drugs Industry

Treatment

- Pulverizing

Material Properties

- Oily

- Non-Oily

Fineness

- 18-400 mesh

Capacity

- 50-400 kg/hr

Production Methods

- Turnkey