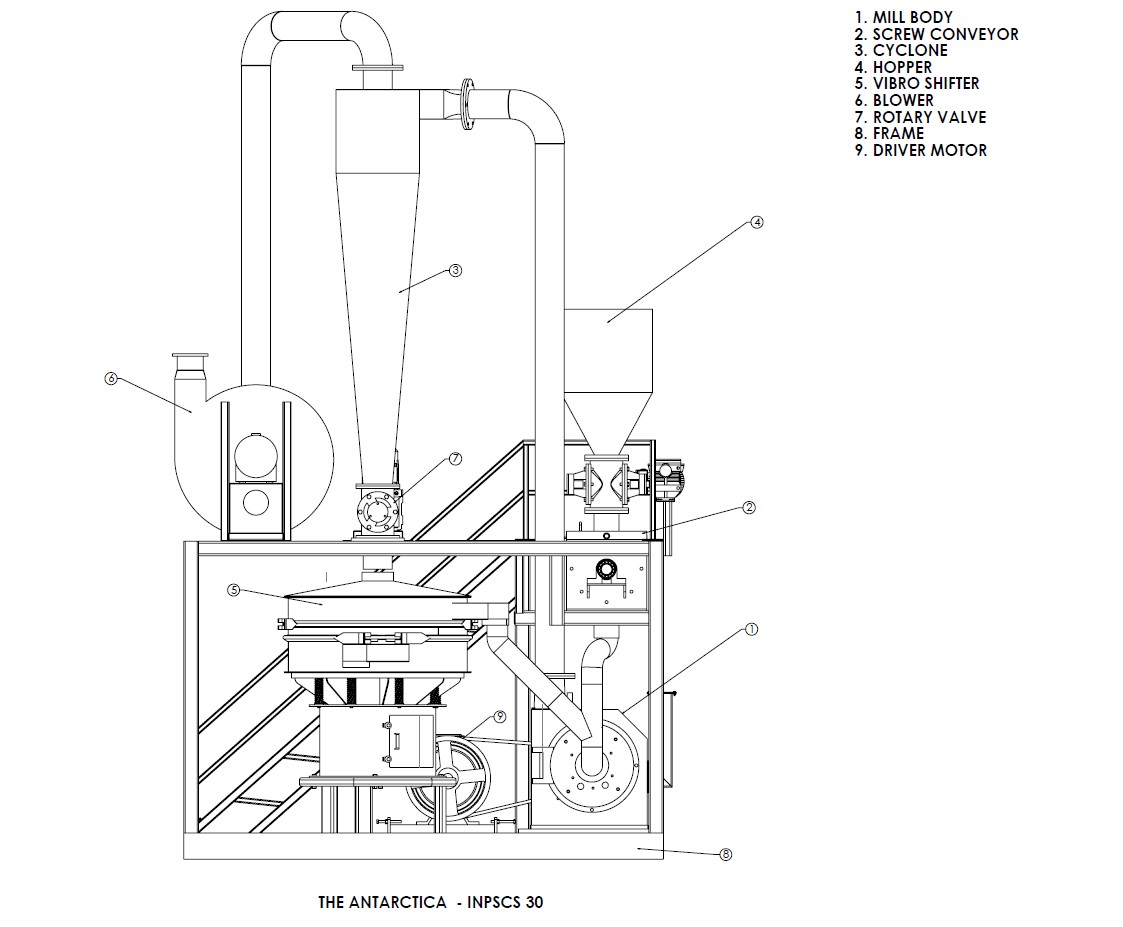

The Antarctic INPSCS

Details

The glass transition point range is extremely wide for any material. The only way to find the material ideal grinding temperature is through numerous testing and collecting large amounts of data. This means that if the temperature changes, it is equivalent as grinding a completely different raw material.

·

Direct and indirect cooling method.

·

High quality insulation

·

Reduce cryogenic fluid consumption,

making the system more energy efficient and cost effective.

·

Automation & Control

·

Modular Design

|

Model Name |

INPSCS – 10 INPSCS – 20 INPSCS – 30 INPSCS – 40 INPSCS – 50 INPSCS – 60 |

|

Applications |

Size Reduction |

|

Field of Application |

Plastic Industry |

|

Feed Material |

Hard, Medium-hard, Soft, Brittle, Elastic,

Fibrous |

|

Size Reduction Principle |

Impact, Friction |

|

Material Feed Size |

8 to 10 mm |

|

No. of Grinding Station |

1 |

|

Cryogenic Grinding |

Yes |

|

Types of Grinding Jars |

Screw Top Design |

|

Material of Grinding Tools |

Stainless Steel, Hardened Steel, Zirconium Oxide, PTEF |

VIDEO

Industries

- Plastic Industry

- Rubber Industry

Treatment

- Pulverizing

Material Properties

- Oily

- Non-Oily

Fineness

- 20-400 mesh

Capacity

- 10-600 kg/hr

Production Methods

- Turnkey