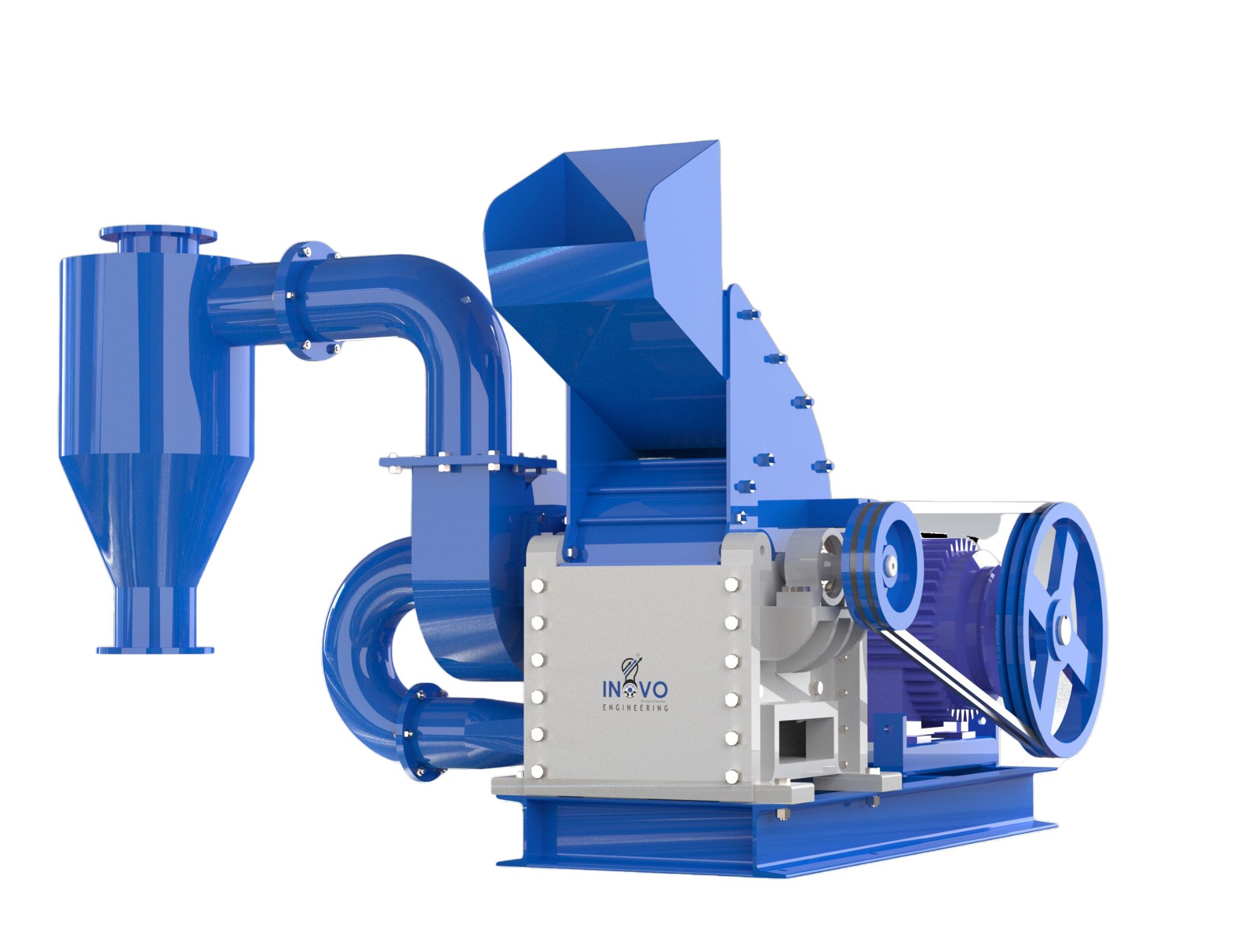

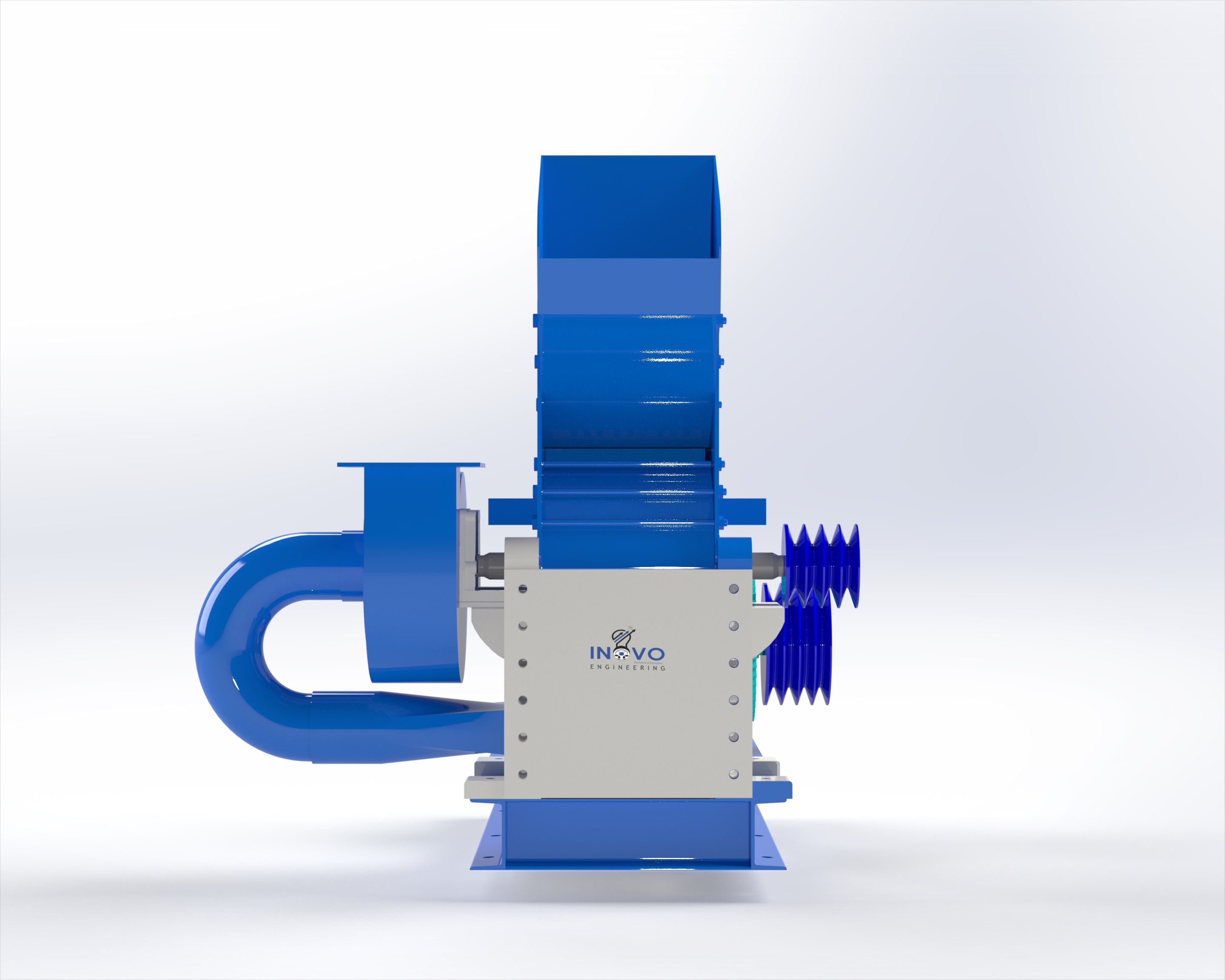

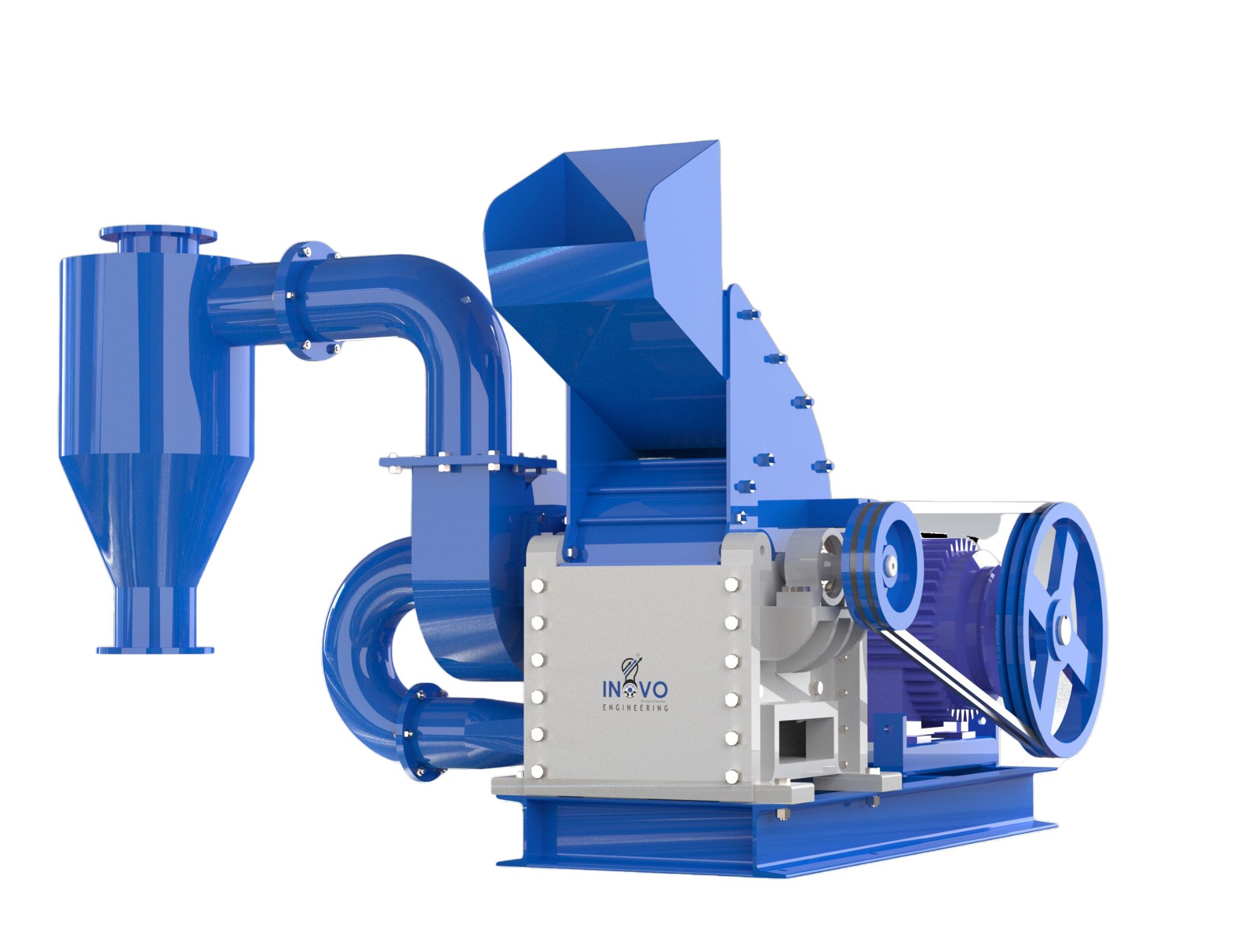

Hammer Mill Machine

Details

Operating Principle:

● Raw Material is fed by screw feeder (single / twin / three screw) on periphery of

the crusher through a hopper into the grinding chamber. It will minimize air

pressure, greatly reducing dust problems.

● For some material suitable ventilation is recommended by introducing air on the

discharge side of the crusher, this will prevent a dusty atmosphere at the inlet of

Mill Crusher.

● The swinging hammers in Mill Crushers crush the materials along the stationery

liners before discharging through a perforated screen at the bottom; replaceable

bar type screen is available for specific application. Different combinations of

screen, hammer can achieve almost any result

● High grinding tip speed up to 20000 fpm & can be adjusted as per requirements.

● Hammer mill Crusher's are specifically designed to withstand the heavy loads to

grind

● abrasive materials.

● Heavy duty, replaceable, wear resistant plates in mill.

● specially treated / hard faced / heat treated hammers.

● Rigid rotor assembly.

● Customized screens / Std. Screens.

● Hammer mill crushers are provided with rubber lining to do Dust-tight or water-

tight operations.

·

Size and Capacity & Rotor Design

·

Speed impact the particle size

distribution and energy efficiency of the mill.

·

Hammer Configuration & Feed

Mechanism

·

Screen Size & Adjustability

·

Cooling Mechanism & Dust Collection

·

Hammer mill is designed for ease

maintenance and cleaning.

VIDEO

APPLICATION

Industries

- Foods Industry

- Herbs Industry

- Chemical Industry

Treatment

- Pulverizing

Material Properties

- Oily

- Non-Oily

Fineness

- 20-400 mesh

Capacity

- 50-1000 kg/hr

Production Methods

- Turnkey