Impact Mill Machine

Details

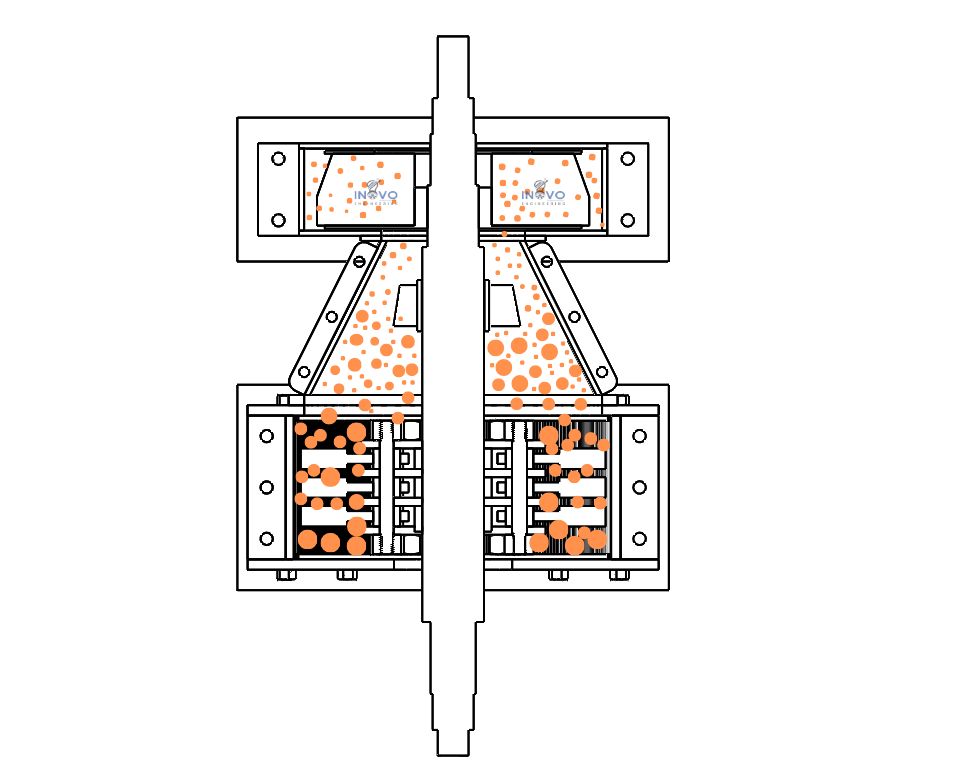

The impact pulverizer consists of an encased rotor carrying swing hammers, whizzer classifier for fineness regulation and pressure gradient creator mounted on a solid shaft. Raw material to be pulverized enters the crushing chamber through the hopper or the automatic rotary feeder. The impact of the hammers on the feed material against the liner plates reduces it into fine powder. The ground material is carried towards the whizzer classifier for classification and the oversize particles are rejected by the classifier and returned to the crushing chamber for further grinding. The classified material is then conveyed into the cyclone for collection and bagging. A dust collector is provided in the system for ensuring dust less operation and for no loss of ground powder.

● High speed rotor assembly two-way reversible hammers / beater

● Easy access to impact pulverizers interior through dual access doors

● Available in different size and models

● Cold and silent running Dust free operations

● Robust construction

● Low specific power consumption

● Durable long life

● Guaranteed grinding efficiency, particle sizes are finer and more uniform than that

obtained from machine using screen

·

Size and Capacity & Motor Power

·

Size and Capacity & Motor Power

·

Speed & Feed Mechanism

·

Material of the mill is important for

durability and suitability for different materials.

·

Screen Size & Adjustability

·

Cooling Mechanism & Dust

Collection

·

Ease of Maintenance

VIDEO

APPLICATION

Industries

- Foods Industry

- Woods Industry

- Herbs Industry

Treatment

- Pulverizing

Material Properties

- Non-Oily

Fineness

- 20-400 mesh

Capacity

- 50-1000 kg/hr

Production Methods

- Turnkey